► Flexible PCB (FPC)

Advantages:

- High Flexibility: FPCs can bend, roll, and fold, accommodating complex three-dimensional layouts and facilitating various design configurations in confined spaces.

- Lightweight: Compared to rigid PCBs, FPCs are typically thinner and lighter, aiding in the reduction of overall product weight.

- Excellent Thermal Dissipation and Solderability: FPCs exhibit superior thermal dissipation properties and are easy to solder, facilitating connections with other electronic components.

- Cost Reduction: In certain applications, FPCs can reduce overall costs by eliminating connectors, wiring harnesses, and assembly steps.

- Shock Resistance: FPCs offer excellent shock absorption capabilities, effectively mitigating vibrations and impacts, and enhancing device durability.

Disadvantages:

- High Initial Cost: Due to the specialized design and manufacturing of FPCs for specific applications, the costs associated with circuit design, routing, and artwork are higher.

- Difficulty in Modification and Repair: Once an FPC is manufactured, modifying the design or repairing the circuitry becomes relatively challenging, as it may require revising the artwork or photo-plotting procedures from scratch.

- Size Limitations: Due to limitations in manufacturing equipment, FPCs are typically subject to certain length and width constraints.

- High Operational Requirements: Assembly personnel require training to avoid damaging the flexible circuit during the handling process.

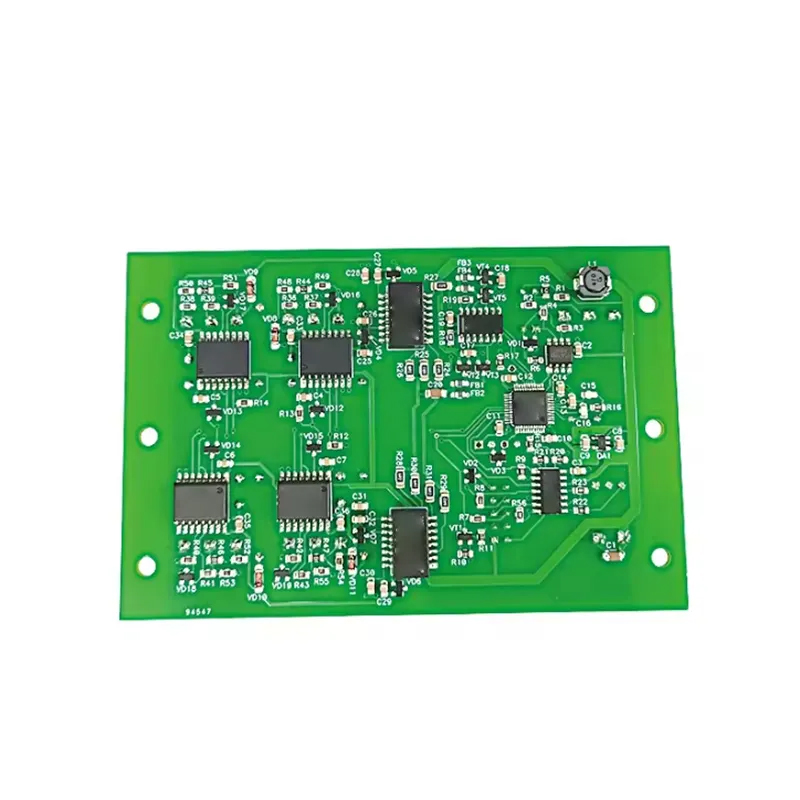

► Rigid PCB

- Structural Stability: Rigid PCBs are made from rigid materials (e.g., fiberglass), providing a sturdy structure capable of enduring high temperatures and gravitational forces.

- Cost-Effectiveness: Rigid PCBs have a relatively lower manufacturing cost, suitable for mass production.

- Ease of Manufacturing and Maintenance: The manufacturing process for rigid PCBs is well-established, and modifications and repairs are straightforward.

- Versatile Applications: Rigid PCBs are suitable for various electronic devices requiring fixed and stable circuit connections, such as desktop computers and televisions.

Disadvantages:

- Lack of Flexibility: Rigid PCBs do not possess bending capabilities, limiting their adaptability to complex spatial layouts.

- Heavier Weight: Compared to FPCs, rigid PCBs are typically thicker and heavier,不利于 reducing overall product weight.

- Inferior Shock Resistance: Rigid PCBs perform less well in absorbing vibrations and impacts compared to FPCs.

Rigid PCBs, indispensable components in the electronics industry, are often the first image that comes to mind when most people think of circuit boards. These boards effectively connect various electrical components by precisely arranging conductive tracks and other elements on a non-conductive substrate. The non-conductive substrate often incorporates glass cloth material to enhance the board's overall strength and ensure sufficient rigidity and durability. These characteristics make rigid PCBs capable of providing stable support for various electronic components and excel in thermal management.

Unlike rigid PCBs, flexible PCBs (FPCs) also have conductive traces on a non-conductive substrate, but they use unique flexible materials such as polyimide (PI). This flexible substrate allows FPCs to withstand vibrations, efficiently dissipate heat, and be folded into various shapes. With these structural advantages, FPCs have become indispensable connecting components in compact electronic devices such as smart wearable devices, mobile phones, and cameras.

In recent years, the market for consumer electronics, led by mobile devices such as smartphones and tablets, has proliferated, with an increasingly significant trend of device miniaturization and lightness. The limitations of traditional PCBs in these areas have gradually emerged, making it difficult to meet market demands. Therefore, major manufacturers have invested in research and development to explore new technologies to replace traditional PCBs. Among these new technologies, FPCs, with their unique advantages, have gradually become the primary connecting components in electronic devices. In addition, driven by emerging markets such as 5G and wearable devices, the application prospects for FPCs will be broader, with significant market growth potential.

In terms of materials, the dielectric layer of FPCs typically uses a homologous sheet of flexible polyimide material. In contrast, rigid PCBs mostly use a composite material of epoxy resin and glass fiber woven cloth as the dielectric material. In terms of solder masks, rigid PCBs have a solder mask on both sides with gaps to expose SMT pads or PTH holes for component assembly. FPCs, on the other hand, often use a conformal coating rather than a solder mask. This conformal coating is a thin polyimide material that can be drilled or laser-cut to access components.

In manufacturing processes, most steps for FPCs and rigid PCBs are similar. However, due to the flexibility of FPCs, special tools are required to fix them in place. In addition, to protect the exposed circuit patterns, FPCs do not use solder masks but instead use processes such as conformal coatings or overlay films.

Although FPCs are slightly more expensive than rigid PCBs in terms of price, they offer many advantages in terms of cost-effectiveness, such as saving space, reducing weight, and improving reliability.